Difference between revisions of "Reference Instructions"

Jump to navigation

Jump to search

| Line 223: | Line 223: | ||

| rowspan="2" style="text-align: center;" | A | | rowspan="2" style="text-align: center;" | A | ||

|- | |- | ||

| − | |[http://l-gauge.org/downloads/ | + | |[http://l-gauge.org/downloads/Ref200MILSBTMSingleRevA.pdf Download Ref Sheet 200 Rev A] |

|- | |- | ||

| rowspan="2" style="text-align: center;" | '''201''' | | rowspan="2" style="text-align: center;" | '''201''' | ||

Revision as of 22:09, 29 August 2016

|

Reference Instruction sheets can be downloaded from the table below. Instruction sheets are provided in PDF format for convenience and should be able to be viewed on nearly all platforms with a suitable PDF viewer application.

Track Related Instructions

| Sheet ID | Preview | Description | Pages | Rev |

|---|---|---|---|---|

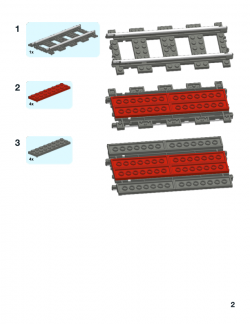

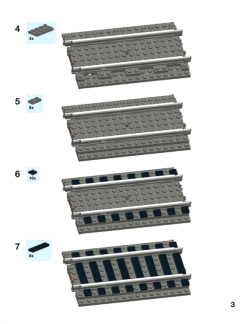

| 001 |

|

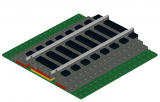

Ballasted Straight Track (PennLUG variation) Instructions to ballast a single full straight track element using the ballasting style first adopted by PennLUG. This finished track item is designed to mount on to a baseplate substrate with plates and tiles to secure the track section. Instructions for the baseplate substrate can be found in reference sheets 002 and 003. |

3 | A |

| Download Ref Sheet 001 Rev A | ||||

| 002 |

|

Ballasted Straight Track Baseplates (16x32) Instructions to make a substrate for straight ballasted track on a 16x32 baseplate. The baseplate colour as well as other items can be substituted as desired. |

1 | A |

| Download Ref Sheet 002 Rev A | ||||

| 003 |

|

Ballasted Straight Track Baseplates (16x16) Instructions to make a substrate for straight ballasted track on a 16x16 baseplate. The baseplate colour as well as other items can be substituted as desired. |

1 | A |

| Download Ref Sheet 003 Rev A | ||||

| 004 |

|

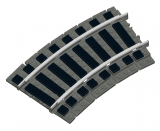

Ballasted R40 Curve Track (PennLUG variation) Instructions to ballast a single R40 curve track element using the ballasting style first adopted by PennLUG. This finished track item is designed to mount on to a baseplate substrate with plates and tiles to secure the track section. Instructions for the baseplate substrate can be found in reference sheet 005. |

4 | A |

| Download Ref Sheet 004 Rev A | ||||

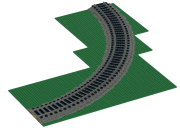

| 005 |

|

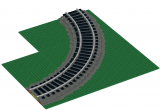

Ballasted R40 Curve Track Baseplates Instructions to make a baseplate substrate for a quarter circle R40 ballasted curve track. Part quantities can be multiplied as necessary to build a half or full circle. The baseplate colour as well as other items can be substituted as desired. |

22 | A |

| Download Ref Sheet 005 Rev A | ||||

| 006 |

|

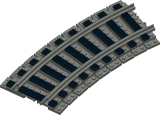

Ballasted R56 Curve Track (PennLUG variation) Instructions to ballast a single ME Models R56 curve track element using the ballasting style first adopted by PennLUG. This finished track item is designed to mount on to a baseplate substrate with plates and tiles to secure the track section. Ballasting method design contributed by Anthony Sava. |

4 | A |

| Download Ref Sheet 006 Rev A | ||||

| 007 |

|

Ballasted R72 Curve Track (PennLUG variation) Instructions to ballast a single ME Models R72 curve track element using the ballasting style first adopted by PennLUG. This finished track item is designed to mount on to a baseplate substrate with plates and tiles to secure the track section. Ballasting method design contributed by Anthony Sava. |

5 | A |

| Download Ref Sheet 007 Rev A | ||||

| 008 |

|

Ballasted R88 Curve Track (PennLUG variation) Instructions to ballast a single ME Models R88 curve track element using the ballasting style first adopted by PennLUG. This finished track item is designed to mount on to a baseplate substrate with plates and tiles to secure the track section. Ballasting method design contributed by Anthony Sava. |

6 | A |

| Download Ref Sheet 008 Rev A | ||||

| 009 |

|

Ballasted R104 Curve Track (PennLUG variation) Instructions to ballast a single ME Models R104 curve track element using the ballasting style first adopted by PennLUG. This finished track item is designed to mount on to a baseplate substrate with plates and tiles to secure the track section. Ballasting method design contributed by Anthony Sava. |

11 | A |

| Download Ref Sheet 009 Rev A | ||||

| 010 |

|

Ballasted R56 Curve Track Baseplates Instructions to make a baseplate substrate for a quarter circle R56 ballasted curve track. Part quantities can be multiplied as necessary to build a half or full circle. The baseplate colour as well as other items can be substituted as desired. |

21 | A |

| Download Ref Sheet 010 Rev A | ||||

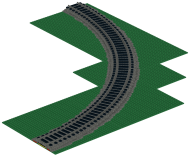

| 011 |

|

Ballasted R72 Curve Track Baseplates Instructions to make a baseplate substrate for a quarter circle R72 ballasted curve track. Part quantities can be multiplied as necessary to build a half or full circle. The baseplate colour as well as other items can be substituted as desired. |

22 | A |

| Download Ref Sheet 011 Rev A | ||||

| 012 |

|

Ballasted R88 Curve Track Baseplates Instructions to make a baseplate substrate for a quarter circle R88 ballasted curve track. Part quantities can be multiplied as necessary to build a half or full circle. The baseplate colour as well as other items can be substituted as desired. |

25 | A |

| Download Ref Sheet 012 Rev A | ||||

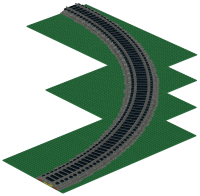

| 013 |

|

Ballasted R104 Curve Track Baseplates Instructions to make a baseplate substrate for a quarter circle R104 ballasted curve track. Part quantities can be multiplied as necessary to build a half or full circle. The baseplate colour as well as other items can be substituted as desired. |

29 | A |

| Download Ref Sheet 013 Rev A | ||||

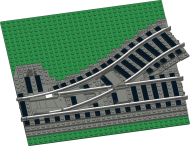

| 014 |

|

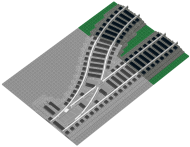

Ballasted Left Switch (even ties/sleepers) Instructions to make a ballasted left-hand track switch including the baseplate substrate. This variation has ties/sleepers located at even stud intervals. Instructions for odd stud intervals are contained in another reference sheet. Instructions for the baseplate substrate for the corresponding parallel return curve can be found in sheet 015. The baseplate colour as well as other items can be substituted as desired. |

20 | A |

| Download Ref Sheet 014 Rev A | ||||

| 015 |

|

Ballasted Left Switch Return Curve Instructions to make a ballasted parallel return curve from a left-hand track switch. Instructions for the corresponding left switch can be found in sheet 014. The baseplate colour as well as other items can be substituted as desired. |

3 | A |

| Download Ref Sheet 015 Rev A | ||||

| 016 |

|

Ballasted Right Switch (even ties/sleepers) Instructions to make a ballasted right-hand track switch including the baseplate substrate. This variation has ties/sleepers located at even stud intervals. Instructions for odd stud intervals are contained in another reference sheet. Instructions for the baseplate substrate for the corresponding parallel return curve can be found in sheet 017. The baseplate colour as well as other items can be substituted as desired. |

20 | A |

| Download Ref Sheet 016 Rev A | ||||

| 017 |

|

Ballasted Right Switch Return Curve Instructions to make a ballasted parallel return curve from a right-hand track switch. Instructions for the corresponding left switch can be found in sheet 016. The baseplate colour as well as other items can be substituted as desired. |

3 | A |

| Download Ref Sheet 017 Rev A |

Bogie / Truck Related Instructions

| Sheet ID | Preview | Description | Pages | Rev |

|---|---|---|---|---|

| 100 |

|

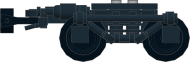

AAR 50 Ton Freight Truck Instructions to make a North American AAR 50 ton freight truck/bogie. This truck design requires the use of non-LEGO® brand brass tubes which are used to mount the train axle wheels. Suitable brass tubes can be obtained from K&S Metals (P/N 8127 or 9821). The train wheel assemblies can be either the older or newer variety (P/N 2878c01 or 2878c02); however the newer variety requires a new brass axle to be cut from 0.081" diameter brass rod (K&S Metals P/N 8168). Credit to Cale Leiphart and Dan Aubin for input on this design. |

4 | D |

| Download Ref Sheet 100 Rev D | ||||

| 101 |

|

AAR Barber S-2 / ASF A-3 Freight Truck Instructions to make a North American 50 ton Barber S-2 or ASF A-3 freight truck/bogie. This freight truck depicts the solid axle bearing type with its distinctive journal boxes. This design of solid axle truck was introduced in the 1940s and were discontinued in 1966. All solid axle trucks were banned from service in 1980. This truck design requires the use of non-LEGO® brand brass tubes which are used to mount the train axle wheels. Suitable brass tubes can be obtained from K&S Metals (P/N 8127 or 9821). The train wheel assemblies can be either the older or newer variety (P/N 2878c01 or 2878c02); however the newer variety requires a new brass axle to be cut from 0.081" diameter brass rod (K&S Metals P/N 8168). Credit to Cale Leiphart and Josh Sanders for input on this design. |

4 | A |

| Download Ref Sheet 101 Rev A | ||||

| 102 |

|

AAR 70 Ton Roller Bearing Freight Truck Instructions to make a North American 70 ton roller bearing freight truck/bogie. Since the discontinuation of solid axle trucks starting in 1966, all modern era freight cars use roller bearing axle trucks. This truck design requires the use of non-LEGO® brand brass tubes which are used to mount the train axle wheels. Suitable brass tubes can be obtained from K&S Metals (P/N 8127 or 9821). The train wheel assemblies can be either the older or newer variety (P/N 2878c01 or 2878c02); however the newer variety requires a new brass axle to be cut from 0.081" diameter brass rod (K&S Metals P/N 8168). Credit to Cale Leiphart and Josh Sanders for input on this design. |

4 | A |

| Download Ref Sheet 102 Rev A | ||||

| 103 |

|

Osgood Bradley Passenger Coach Truck Instructions to make a North American Osgood Bradley lightweight passenger coach truck/bogie. This truck design requires the use of non-LEGO® brand brass tubes which are used to mount the train axle wheels. Suitable brass tubes can be obtained from K&S Metals (P/N 8127 or 9821). The train wheel assemblies can be either the older or newer variety (P/N 2878c01 or 2878c02); however the newer variety requires a new brass axle to be cut from 0.081" diameter brass rod (K&S Metals P/N 8168). Credit to Matt Csenge and Vinnie Fusca for input on this design. |

6 | A |

| Download Ref Sheet 103 Rev A | ||||

| 104 |

|

3-Axle Heavyweight Passenger Coach Truck Instructions to make a North American 3-axle heavyweight passenger coach truck/bogie. This truck design requires the use of non-LEGO® brand brass tubes which are used to mount the train axle wheels. The centre axle must have free lateral movement of at least ±2mm in order to negotiate curves and switches. This can be achieved by cutting the brass axle bearing shorter than the outer fixed axle bearings. Suitable brass tubes can be obtained from K&S Metals (P/N 8127 or 9821). The train wheel assemblies can be either the older or newer variety (P/N 2878c01 or 2878c02); however the newer variety requires a new brass axle to be cut from 0.081" diameter brass rod (K&S Metals P/N 8168). Credit to Nate Brill, Matt Csenge and Vinnie Fusca for input on this design. |

5 | A |

| Download Ref Sheet 104 Rev A |

MILS Modules Instructions

| Sheet ID | Preview | Description | Pages | Rev |

|---|---|---|---|---|

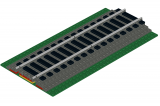

| 200 |

|

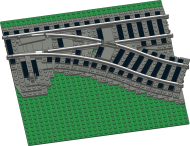

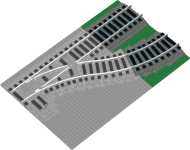

MILS Basic Terrain Module (BTM) Base for Single Track Instructions to build a MILS compatible mounting base for ballasted straight single track. Instructions for the ballasted straight track sections can be found in reference sheet 001. |

6 | A |

| Download Ref Sheet 200 Rev A | ||||

| 201 |

|

MILS Basic Terrain Module (BTM) Base for Double Track Instructions to build a MILS compatible mounting base for ballasted straight double track. Instructions for the ballasted straight track sections can be found in reference sheet 001. |

8 | A |

| Download Ref Sheet 201 Rev A |